There are many different varieties of pumps used in the industries. They are as listed below:

- Centrifugal pump

- Positive displacement pump

- ANSI process pump

- API process pump

- Axial flow pump

- Booster pump

- Canned motor pump

- Chopper pump

- Circulator pump

- Cryogenic pump

- Drum pump

- End suction pump

- Fire pump

- Grinder pump

- Horizontal split-case pump

- Jet pump

- Magnetic drive pump

- Multistage pump

- Regenerative turbine pump

- Slurry pump

- Self-priming pump

- Submersible pump

- Trash pump

- Vertical sump pump

- Vertical turbine pump

- Well pump

- AODD pump

- Concrete pump

- Diaphragm pump

- Flexible impeller pump

- Gear pump

- Lobe pump

- Metering pump

- Peristaltic pump

- Piston pump

- Plunger pump

- Progressive cavity pump

- Screw pump

- Vane pump

We will discuss in this post about 2 common types of Sanitary Pumps.

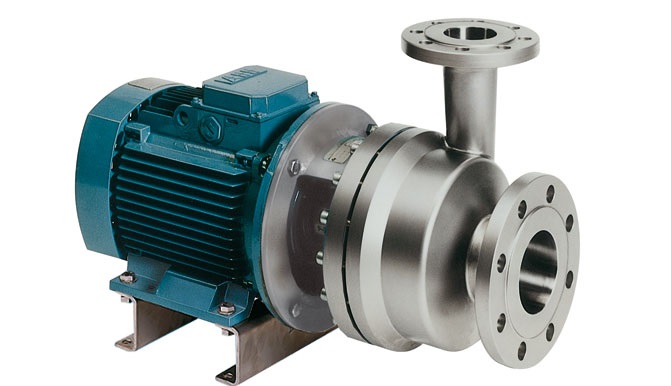

Centrifugal pump

- Basic description

This is general name for the pumps having one or more number of impellers. They can be configured based on their applications.

- Key features

There can be one impeller or more too. Casing can be diffuser or volute type. Usually, it will be driven by electric motor, but other types of drive are also available.

- Application

All kinds of liquids are pumped by these centrifugal pumps. Can achieve highest flow rates as compared to all pump types. It can handle dirty or clean liquids, and also liquid with low viscosity.

- Advantages

For lower of lower viscosity, it can be best pump choice that can also achieve high flow rates. You cannot find any pulsation that are often found in few positive displacement pumps.

Positive displacement pump

- Basic description

This type of pump does not have their impellers, but relies on its rotating/reciprocating parts, in order to directly push all the liquid in enclosed volume, till enough pressure will be built up for moving the liquid into discharge system.

- Key features

Pump will work on principle of positive displacement, either reciprocating or rotary.

- Application

All kinds of services in different industries where such positive displacement pumps can be preferred over centrifugal pumps because of shear sensitive solids, high viscosity or need for high pressure and low flow.

- Advantages

For higher viscosity liquids, it is best choice, and can move liquids gently. Also, suitable for low flow with high pressure combination.